Concrete fibres are advanced reinforcement materials that significantly improve the overall performance of concrete. By being integrated directly into the concrete mix during the batching process, these fibres ensure consistent and multidirectional reinforcement throughout the entire concrete structure. This enhancement leads to increased strength, durability, and resistance to cracking.

Polypropylene (PP) fibres improve the plastic shrinkage and thermal cracking resistance of concrete. They are lightweight, corrosion-resistant, and reduce the permeability of concrete, enhancing its durability and longevity. In tunnel construction, preventive fire protection has become crucial. By incorporating synthetic fibres, the concrete gains protective properties, reducing or preventing explosive spalling. Our polypropylene fibres, developed through extensive research, have proven effective in this regard.

| Product Information |

|---|

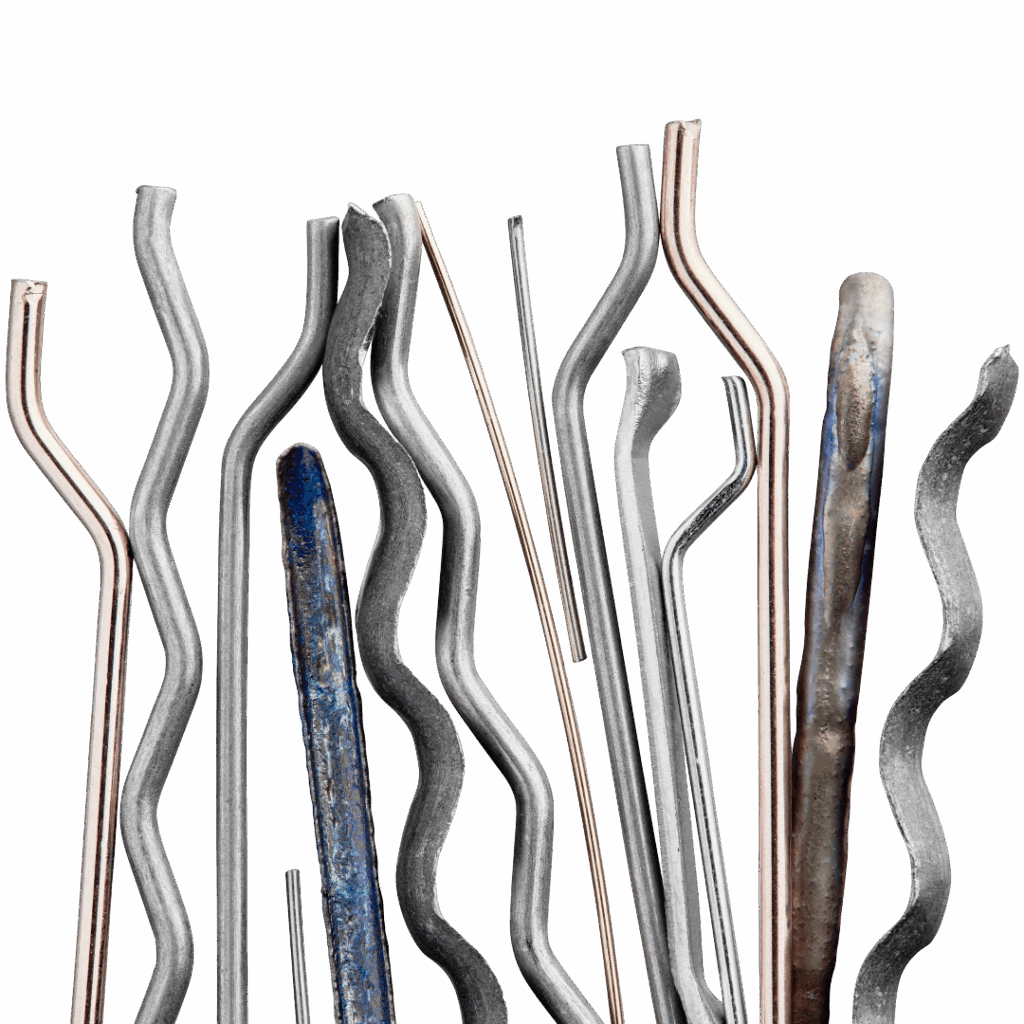

Types of Fibres

We supply a comprehensive range of fibre types to meet diverse project and performance requirements:

- Steel fibres – Increase load-bearing capacity, toughness, and impact resistance.

- Synthetic macro fibres – Provide structural reinforcement, replacing traditional steel mesh and improving post-crack performance.

- Synthetic micro fibres – Minimize micro-cracking and enhance surface durability and finish quality.

Krampe Harex

KrampeHarex is a leading company in infrastructure and tunnel construction technology, distinguished by its innovative solutions and sustainable approaches. With decades of experience and a strong focus on quality, KrampeHarex offers customized products and services that meet the highest industry standards. Their commitment to sustainability is evident in the use of environmentally friendly materials and energy-efficient processes, which not only extend the lifespan of tunnel structures but also minimize environmental impact. Trust KrampeHarex to realize your tunnel construction projects safely, efficiently, and sustainably.

Key features of KrampeHarex

- Specialized solutions for tunnel construction

- Fibers optimized for shotcrete and segmental lining applications

- Increased safety and stability under extreme loads

- Sustainability & EPD certification

- Official EPD for steel fibers

- Lowest GWP on the market – relevant for infrastructure projects with sustainability requirements

- German production & quality “Made in Germany”

- Manufactured in Germany with state-of-the-art machinery

- Highest quality standards and process reliability for large-scale projects

- Technical advice & support

- Support with formulation, dosing, and mixing

- Experience from international tunnel projects

- Integrated dosing technology

- KrampeHarex dosing equipment for precise and efficient fiber addition

- Reduces errors, saves time and costs on the construction site

- Personal service & project support

- Direct contact person for tunnel construction projects

- Fast response times and customized solutions

- Long-term partnership

- Focus on TCO optimization and sustainability

- Reliability for large-scale projects and tight schedules

Applications

- Industrial floors

- Tunnel linings and shotcrete

- Precast concrete components

- Refractory concrete.

- Residential construction

- Security hardened elements

- UHPC

Quality Assurance

Our fibres are manufactured and tested in accordance with ASTM C1116, EN 14889, and other relevant international standards, ensuring consistent performance, reliability, and compliance with the most demanding project specifications.