As urban populations grow and infrastructure demands increase, tunnel boring machines have become indispensable for developing underground infrastructure across the Middle East and globally. From metro tunnel construction to road tunnel boring and sewer tunnel projects, these sophisticated machines are revolutionizing how we build beneath our cities.

What is a Tunnel Boring Machine?

A tunnel boring machine (TBM) is a sophisticated piece of engineering equipment designed to excavate tunnels through various soil and rock conditions. Often called a “mole,” these massive machines can bore through earth at rates of 50-60 feet per day, creating precise circular tunnels for metro systems, utilities, roadways, and railways with minimal surface disruption.

Modern tunnel construction requires precision, efficiency, and safety—qualities that make tunnel boring machines essential for infrastructure development projects worldwide. At Foster International, we understand the critical role that supporting systems like tunnel segment gaskets and seismic protection systems play in ensuring the longevity and safety of these ambitious projects.

How Does a TBM Work?

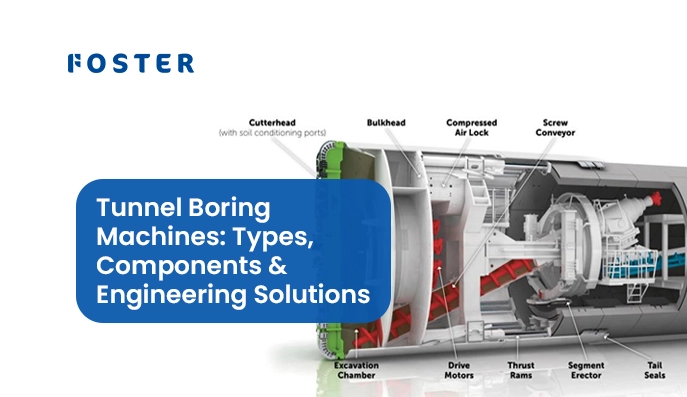

Understanding TBM components is essential to appreciating the complexity of tunnel excavation technology. A typical tunnel boring machine consists of three main sections:

1. Cutting Head (Front Section)

The cutter head is the business end of the TBM, equipped with disc cutters that rotate and apply tremendous pressure to break rock or soil. The cutter head design varies significantly based on ground conditions, with hard rock TBM systems using different cutting tools for TBM operations compared to soft ground applications.

2. Shield and Support Systems (Middle Section)

The shield section houses the TBM gripper systems and provides temporary support to the excavated tunnel walls. This is where tunnel segment installation occurs, with precast concrete segments being placed to form the permanent tunnel lining systems. Critical components like tunnel segment gaskets are installed here to ensure tunnel waterproofing solutions are effective.

3. Trailing Gear and Backup Systems (Rear Section)

The TBM backup systems contain essential equipment including ventilation, power supply, material transport, and control systems. The TBM trailing gear manages the removal of excavated material (muck) through conveyor systems that transport debris out of the tunnel.

Types of Tunnel Boring Machines

Selecting the right TBM depends on geological conditions, project requirements, and environmental constraints. Here are the main types of tunnel boring machines used in modern construction:

Hard Rock TBM

Hard rock TBM machines are designed for excavating through solid rock formations. These open-type machines use disc cutters mounted on the rotating cutter head to chip away at rock through compressive stress fractures. Main beam TBM and double shield TBM configurations are common in hard rock applications, similar to technologies used in major infrastructure projects worldwide.

Key Features:

- Powerful disc cutters for rock penetration

- Gripper systems that brace against tunnel walls

- Minimal ground support requirements during excavation

- Ideal for rock with compressive strength above 10 MPa

Soft Ground TBM

Soft ground TBM machines are engineered for soil, clay, sand, and weak rock conditions. These machines require more sophisticated ground control in tunneling to prevent collapse and manage groundwater. The three primary soft ground configurations include:

Earth Pressure Balance TBM

The earth pressure balance TBM (EPB) is one of the most versatile soft ground machines. It maintains face stability by using the excavated material itself as support, plasticizing it within a sealed chamber. A screw conveyor removes the conditioned soil while maintaining pressure balance—eliminating the need for slurry systems.

Applications:

- Metro tunnel construction in urban environments

- Tunneling in urban areas with sensitive structures

- Mixed ground conditions with water pressure below 7 bars

Slurry Shield TBM

The slurry shield TBM operates by filling the excavation chamber with pressurized bentonite slurry, which provides hydrostatic support to the tunnel face. The slurry also serves as a transport medium, carrying excavated material to separation plants where it’s filtered and recycled.

Best Suited For:

- Granular soils with high water pressure

- Underwater tunnel crossings

- Environments requiring maximum face stability

Open Face TBM

Open face TBM designs provide no frontal support, relying on the inherent stability of the ground being excavated. Single shield TBM machines often employ this method in competent ground that can stand unsupported temporarily. The shield advances in sync with excavation, allowing immediate installation of tunnel lining systems.

Crossover TBM Machines

Crossover TBM machines offer the flexibility to operate in both hard rock and soft ground conditions. These adaptable systems can switch modes based on changing geology, making them ideal for projects with variable ground conditions—common in infrastructure development projects across diverse terrains.

Critical TBM Components and Their Functions

Disc Cutters and Cutting Tools

The cutting system is the heart of any TBM. Disc cutters range from 17 inches for smaller machines to over 20 inches for large-diameter TBMs. The spacing, size, and configuration of cutting tools for TBM operations directly impact TBM advance rates and overall project efficiency.

TBM Gripper and Shield Systems

TBM gripper systems provide the reaction force necessary for the cutter head to penetrate rock. In shielded machines, the TBM shield systems protect workers and provide a stable environment for tunnel segment installation while the machine advances.

Segment Erection and Gasket Systems

As the TBM advances, precast concrete segments are installed to form the permanent tunnel structure. Tunnel segment gaskets—a critical component supplied by specialized civil engineering firms like Foster International—seal the joints between segments, preventing water ingress and ensuring long-term structural integrity. These gaskets must meet strict international standards for durability and performance in demanding underground conditions.

TBM Construction Stages: From Planning to Completion

Understanding TBM construction stages is essential for project success:

- Site Preparation and Shaft Excavation: Launch and retrieval shafts are excavated to allow TBM assembly and removal.

- TBM Assembly: The machine is assembled underground at the launch shaft, a process that can take several weeks depending on TBM size.

- Excavation and Tunneling: The TBM advances through the ground, with continuous monitoring through tunnel monitoring systems and geotechnical monitoring equipment.

- Segment Installation: As excavation progresses, tunnel lining systems are erected, complete with essential tunnel waterproofing solutions including high-quality tunnel segment gaskets.

- TBM Retrieval: Upon breakthrough, the machine is disassembled and either transported to another project or refurbished.

Advantages of Tunnel Boring Machines

Superior Safety and Control

TBM excavation provides a safer working environment compared to conventional drill-and-blast methods. The enclosed nature of TBM operations protects workers from rock falls and provides better control over ground movement control in sensitive urban environments.

Minimal Surface Disruption

For tunneling in urban areas, TBMs offer the significant advantage of minimal surface disruption. This is particularly crucial for metro tunnel construction beneath existing infrastructure, where ground loss monitoring and precise control are paramount.

Consistent Quality and Speed

Modern tunnel boring machines achieve consistent TBM advance rates, with some projects exceeding 100 feet per day in favorable conditions. The uniform excavation profile reduces the need for excessive ground support and streamlines tunnel segment installation.

Environmental Benefits

Compared to cut-and-cover methods, TBM excavation generates less noise, vibration, and surface disturbance—critical factors in densely populated areas where rail tunnel construction and road tunnel boring projects are increasingly common.

Supporting Infrastructure: The Role of Quality Components

While tunnel boring machines capture attention with their impressive engineering, the success of any tunnel project depends equally on supporting components. At Foster International, we specialize in providing essential infrastructure elements that ensure tunnel longevity and performance:

- Tunnel Segment Gaskets: Premium sealing solutions that meet stringent tunnel segment gasket requirements for waterproofing and durability

- Expansion Joints: Critical for accommodating thermal movement in tunnel structures

- Seismic Protection Systems: Advanced isolation systems that protect tunnels in seismically active regions

- Bridge Bearings: Supporting infrastructure projects beyond tunnels

These components work in concert with tunnel excavation technology to create infrastructure that serves communities safely for decades.

The Future of Underground Construction

As cities across the UAE, India, and globally continue to expand downward, tunnel boring machines will play an increasingly vital role in infrastructure development. Innovations in TBM technology, coupled with advanced tunnel monitoring systems and improved tunnel waterproofing solutions, are making deeper, longer, and more complex tunnel projects feasible.

Whether you’re planning metro tunnel construction, sewer tunnel projects, or any underground infrastructure initiative, understanding tunnel boring machines and their supporting systems is essential. The integration of reliable TBM technology with high-quality components like tunnel segment gaskets ensures projects that meet the demanding standards of modern civil engineering.

Partner with Foster International for Your Tunnel Infrastructure Needs

Foster International brings decades of expertise in architecture and civil engineering solutions to the Middle East and Indian markets. While tunnel boring machines excavate the path forward, we provide the critical components—from tunnel segment gaskets to seismic protection systems—that ensure your underground infrastructure stands the test of time.

Our partnerships with globally recognized brands like FIP MEC and CTS Cordes guarantee access to world-class tunnel lining systems, tunnel waterproofing solutions, and structural support components for your most demanding projects.

Contact Foster International today to discuss how our civil engineering solutions can support your next tunnel construction project, ensuring quality, durability, and long-term performance in every segment.

Previous Post

Previous Post